Inventory management problems can disrupt your business operations. They lead to lost sales and increased costs.

Effective inventory management is crucial for any business. Yet, many struggle with common issues that can hinder success. Stockouts, overstocking, and inaccurate records are just a few of the challenges faced. These problems can strain resources, affect customer satisfaction, and impact profits.

Understanding and addressing these issues is essential to streamline processes and maintain a healthy bottom line. In this post, we’ll delve into the most prevalent inventory management problems. We will also explore practical solutions to help you manage your inventory more efficiently. Stay tuned to transform your inventory management and boost your business performance.

Common Inventory Issues

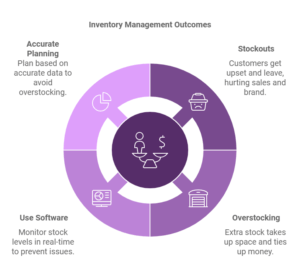

Stockouts happen when there is no stock left. Customers get upset and leave. This can hurt sales and your brand. Stockouts can happen due to poor planning. Sometimes, high demand also causes stockouts. It’s important to keep track of inventory levels. Use software to monitor stock levels in real-time.

Overstocking means having too much stock. This can be costly. Extra stock takes up space. It ties up money that could be used elsewhere. Products may become outdated or spoiled. Overstocking happens due to inaccurate forecasts. Sometimes, ordering in bulk leads to overstocking. To avoid this, use inventory management tools. Plan based on accurate data.

Inefficient Processes

Poor inventory management can lead to inefficient processes. This results in wasted time, increased costs, and lost sales opportunities. Streamlining these processes is crucial for business success.

Manual Tracking

Manual tracking is slow and prone to errors. Workers often make mistakes. These mistakes lead to lost items and wrong counts. Incorrect data impacts the whole business. It wastes time and resources. Employees spend hours on simple tasks. This reduces productivity and efficiency. Businesses need better ways to track inventory.

Lack Of Automation

Without automation, processes become slow and clunky. Tasks take longer to complete. Staff manually enters data, which can have errors. Errors cause delays and mismanagement. Automation can help with accuracy. It saves time and reduces mistakes. Lack of automation impacts customer satisfaction. Quick and accurate service is crucial for success.

Poor Demand Forecasting

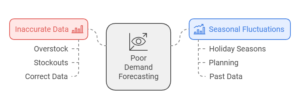

Inaccurate data causes many problems. It leads to poor demand forecasting. Wrong data means you may order too much or too little. This can lead to overstock or stockouts. Both are bad for business. It is important to have correct data. Use reliable sources and tools for data.

Seasonal fluctuations affect demand forecasting. Holiday seasons can cause big changes in demand. If you do not plan, you will face problems. Too much stock means wasted money. Too little stock means lost sales. It is key to predict these changes. Use past data to plan for future seasons.

Supply Chain Disruptions

Problems with supplier reliability can hurt your inventory. Sometimes, suppliers delay shipments. This can lead to stock shortages. In some cases, suppliers may not deliver the correct items. Quality issues from suppliers can cause returns and losses. The trust between businesses and suppliers is very important. Having backup suppliers can help reduce risks.

Logistics delays are common in inventory management. Traffic jams can slow down deliveries. Bad weather can also delay shipments. Sometimes, there are customs issues with international shipments. These delays can lead to stockouts. Customers may get upset if they do not get their items on time. Planning and having a buffer stock can help manage these delays.

Inventory Visibility

Not having real-time data leads to many problems. Stock levels can be incorrect. This causes overstocking or stockouts. Both are bad for business. Overstocking ties up money. Stockouts lead to lost sales. Updating data manually is hard. It takes a lot of time. Errors happen often.

Reports need to be accurate. Inconsistent reporting makes it hard to see the true inventory levels. Different departments may have different numbers. This causes confusion. Decisions based on wrong data are bad. It leads to mistakes. Mistakes cost money and time.

Cost Management

Carrying costs are the expenses to store unsold goods. These costs include rent, utilities, and insurance. Also, the money tied up in inventory adds to these costs. Companies must manage these costs to stay profitable. Reducing excess stock helps lower these expenses.

Shrinkage happens due to loss of inventory. Theft, damage, or errors cause shrinkage. It affects profits and increases costs. Regular audits and better security help reduce shrinkage. Training staff can also prevent mistakes that lead to shrinkage.

Technological Integration

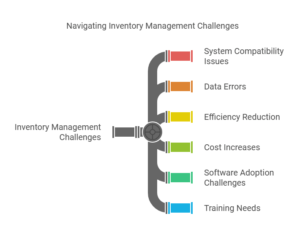

Many businesses face issues with system compatibility in inventory management. Different systems may not work well together. This can lead to data errors and lost information. Having systems that do not match causes delays. Workers may spend extra time fixing these problems. This reduces efficiency and increases costs. Integrating compatible systems is key to smooth operations.

Adopting new software can be hard for businesses. Employees may struggle to learn new tools. Training takes time and money. Some may resist change. This can slow down inventory processes. Old software might not support new features. This makes it hard to stay competitive. Choosing the right software helps avoid these issues. Regular updates keep systems running smoothly.

Effective Solutions

Automation can help reduce manual errors. It speeds up tasks like counting stock. This can save time and money. Automated systems keep track of items in real-time. This ensures accurate inventory records. Employees can focus on other important tasks. Automation makes your business run smoother.

Advanced analytics give detailed insights into inventory data. It helps predict future demand. This reduces the risk of overstocking or stockouts. Analytics tools can identify trends and patterns. This helps make better decisions. Businesses can plan more effectively.

Frequently Asked Questions

What Are Common Inventory Management Problems?

Common inventory management problems include overstocking, understocking, inaccurate inventory records, and inefficient warehouse management. These issues can lead to increased costs and lost sales opportunities.

How Can Overstocking Affect Your Business?

Overstocking can tie up capital, increase storage costs, and lead to obsolete inventory. This affects cash flow and profitability.

Why Is Accurate Inventory Tracking Important?

Accurate inventory tracking helps maintain optimal stock levels, reduce costs, and improve customer satisfaction. It ensures timely order fulfillment.

What Causes Understocking Issues?

Understocking issues are often caused by poor demand forecasting, inadequate reorder points, and supplier delays. This can result in lost sales and customer dissatisfaction.

Conclusion

Effective inventory management is crucial for business success. Common problems can disrupt operations. Addressing these issues early can save time and money. Implementing better systems and training staff are key steps. Regular audits help identify and fix problems quickly. Streamlining processes improves efficiency and customer satisfaction.

Remember, a well-managed inventory boosts profits and reduces stress. Invest in solutions to keep your inventory in check. This leads to a smoother, more profitable business journey.